January

The nesting blocks are stripped of their larvae with cocoon extraction machines which harvest loose cell cocoons. The loose cocoons are bagged and stored at a cool temperature to maintain dormancy.

February

Empty styrofoam nesting blocks are put back together with straps and stacked ready to go back to the field in the spring.

Empty nesting blocks which have been through the extracting machine

Stacks of nesting block units ready for the field

Blocks full of larvae are cut and stamped for Backyard Pollinators, the wooden bee barns are branded and stacked ready for the upcoming season.

Block which have been cut & stamped

Applying the branding iron to a barn

Stacks of pre-built cedar barns ready for sale

March

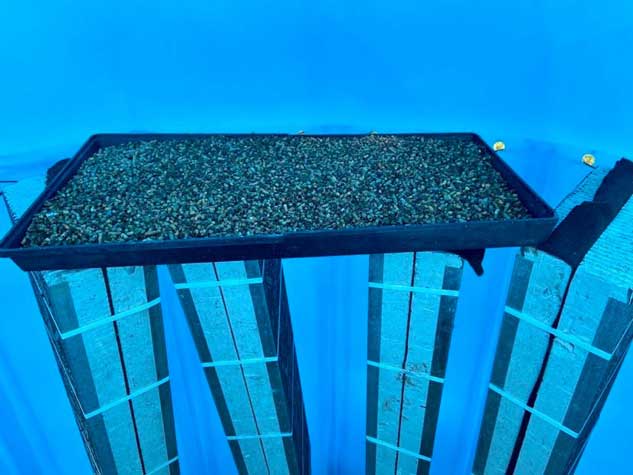

200 bags of loose cell cocoons will be measured into 1,500 incubation trays. The trays are stored in cooled rooms which keeps the larvae in a dormant state until we begin incubating the bees in early June.

Jody measuring bees

Tray of Cocoons

Racks of incubation trays

April

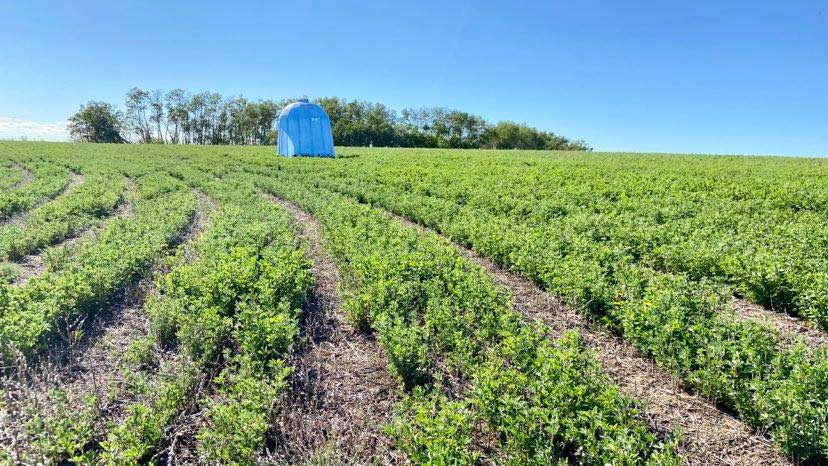

When the weather warms up and the ground unthaws we can proceed with shifting the blue bee huts into new stands of alfalfa. A GPS is used to make sure that the rows of huts are straight.

Shifting bee domes to a new field

Inside a bee dome

As people begin planning their gardens the online ordering of Backyard Pollinators gets busy, our local post office sends our packages safely on their way.

Cedar bee barn

Unstained bee barn

Busy day of shipping orders

May

Planting of our crops commences, we typically grow lentils, wheat, oats and canola. The perennial alfalfa plants begin to send up new growth.

Getting the equipment ready for the field

Budding alfalfa plant

Healthy stand of alfalfa in the spring

Truckloads of nesting blocks are taken to the field and hung inside the bee huts, there are usually 12 doubled-up units in each hut.

Loading nesting blocks for the field

Nesting blocks hang inside a hut

Blocks hang neatly side by side

June

The month of June causes both anxiety and excitement, imagine knowing that 60 million babies will arrive in 4 weeks! The incubation rooms are heated to 30C and very closely monitored. Bees begin to emerge around Day 23, the weather and development of the alfalfa crops determines when we release the hatched bees.

Jed checks the incubation temperature of the trays

The ideal temperature for hatching bees is 30C

Blossoming alfalfa, ready for bees

The night before we take bees to the field we cool the incubation rooms (to calm the bees) and remove the tray lids. Early the next morning the truck is loaded with trays of hatched bees. At the field trays are placed on top of the nesting blocks to keep them dry.

Mark wheels trays of hatched bees to the truck

Kathy holds a tray of bees inside a loaded truck

Jed & Kathy ready to place trays of bees inside the hut

Beautifully colored male bees

A tray of bees safe and dry on top of the nesting blocks